SAM semi-autogenious and autogenious mills

Benefits of cutting-edge SAG and AG mill designs, engineered for robustness and optimized for high availability

Experience the efficiency and reliability of our robust autogenous and semi-autogenous mills, which surpass conventional secondary and tertiary crushing circuits by achieving higher throughputs.

With combining crushing and grinding capabilities, our SAM mills streamline your grinding operations.

Autogenous mills provide a cost-effective alternative without compromising performance. Powered by rotary motion, the material is effortlessly lifted, crushed, and comminuted by itself. Semi-autogenous mills operate by incorporating the use of steel grinding media, typically ranging between 8% and 15% of the mill volume.

In many scenarios, ball mills are utilized for further processing of the product from autogenous (AG) or semi-autogenous (SAG) mills. However, there are instances where single-stage AG/SAG mills can already achieve the desired final fineness, eliminating the need for additional grinding stages.

Discover the next level of grinding excellence with our advanced mill solutions.

Technical details

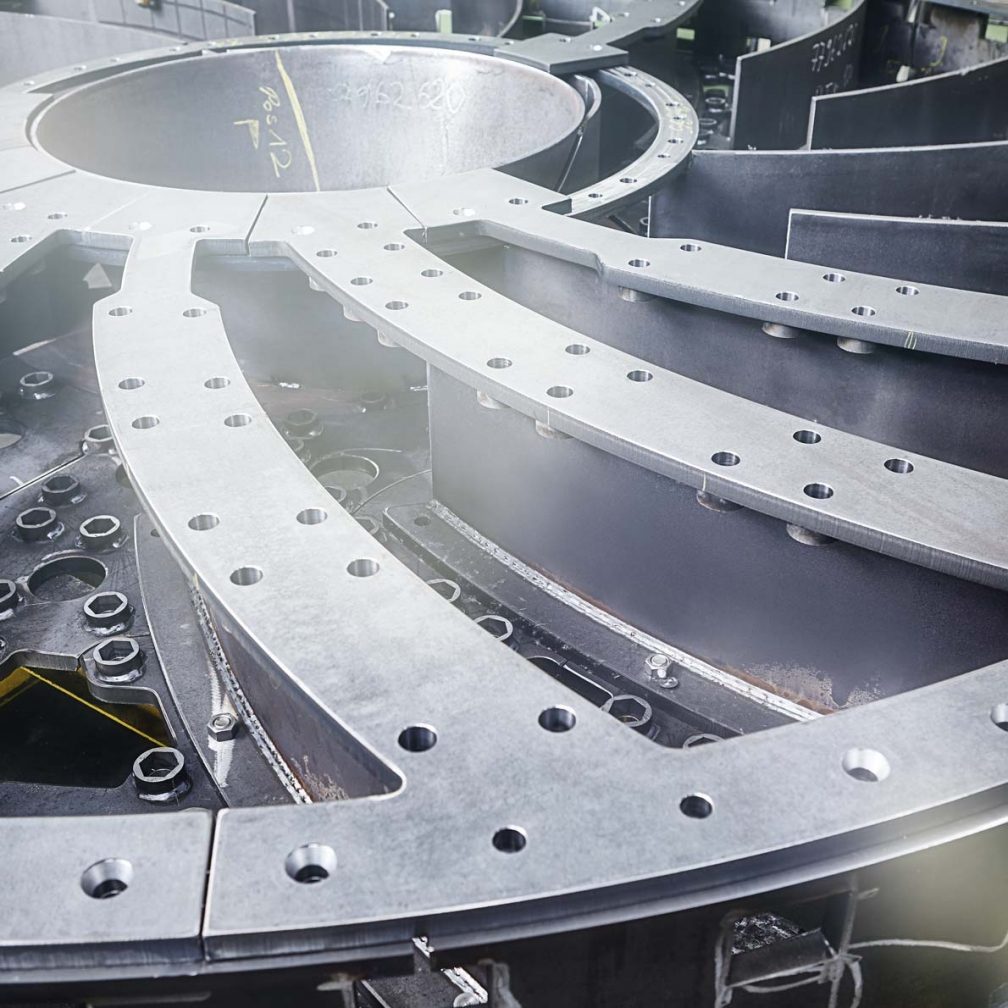

- Power of Longevity: Durable mill body design with advanced FEA (Finite Element Analysis) for maximum lifespan.

- Optimal Performance and Reliability: Trunnion-supported with sleeve bearings or shell-supported design with slide shoe (pad) bearings.

- Powerful Drive Solutions: Up to 18 MW capacity, featuring ring gear and conventional single/dual pinion or direct meshing gearboxes, in combination with high-speed asynchronous or low-speed synchronous motors.

- Reliable Lubrication Systems: Ensuring smooth operation with standby pumps for hydrostatic and hydrodynamic lubrication.

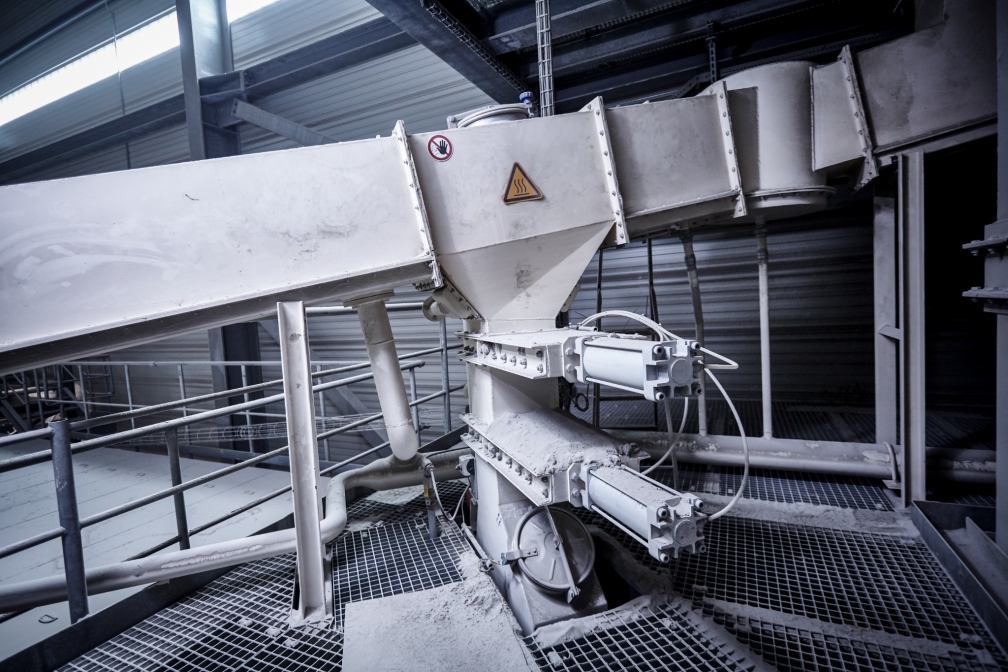

Heavy-duty Feed Chutes: Equipped with "rock box" and replaceable liners, designed to withstand demanding conditions.

Efficient Discharge Solutions: Trommel screen mounted on mill discharge trunnion or discharge spouts for usage of vibration screens through seamless integration.

more than

100 ball mill

installations worldwide

How does comminution with an autogenous or semi-autogenous mill work?

Comminution in autogenous or semi-autogenous mills relies on the self-grinding action of the material. As the mill rotates, the feed material is lifted by the shell lining, and due to gravity, it falls down, resulting in material impact and breakage. This self-grinding process occurs in autogenous mills.

When ore properties are inadequate for autogenous grinding, the addition of steel grinding media compensates in semi-autogenous mills. The media replaces larger rocks, enabling impact breakage and achieving the desired comminution in a flexible and versatile manner.

Why a large mill diameter with a short length?

AG/SAG mills are commonly characterized by a large mill diameter and short length, resulting in a high aspect ratio. This configuration offers benefits for achieving high throughput and coarser product fineness. The larger diameter generates the required breakage energy for efficient comminution. Following AG/SAG milling, the product is often passed on for further processing in ball mills to achieve the desired final particle size and product specifications. Typical length to diameter ratio of such AG/SAG mills is approx. 0,5.

In certain situations where a finer product is desired and a longer residence time in the mill is necessary, the ore can be processed in a single-stage AG/SAG mill. This is achieved by utilizing longer mills with a low aspect ratio. These mills have length to diameter ratios typically in the range of 1 or higher, often referred to as "square" mills.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.