Complementary products

for your process

Equipment for special requirements

For many of our customers it is worthwhile to expand the grinding plants with components for cooling and sorting. The powder cooler by Christian Pfeiffer improves product quality through cooling, the grinding ball sorting machine optimizes the ball charge of the grinding plant, and our foreign object trap intercepts foreign material, prevents it from returning to the grinding process, and thus protects the separator from damage. To control the temperature during grinding, we offer water injection systems.

CoolER

Reduce temperature, improve product quality

In order to improve its general or specific product quality, it is often necessary to cool the ground material directly after comminution. A powder cooler by Christian Pfeiffer is the right solution. It is suitable for all powdery products, semolina and circulating material from grinding plants or similar production processes.

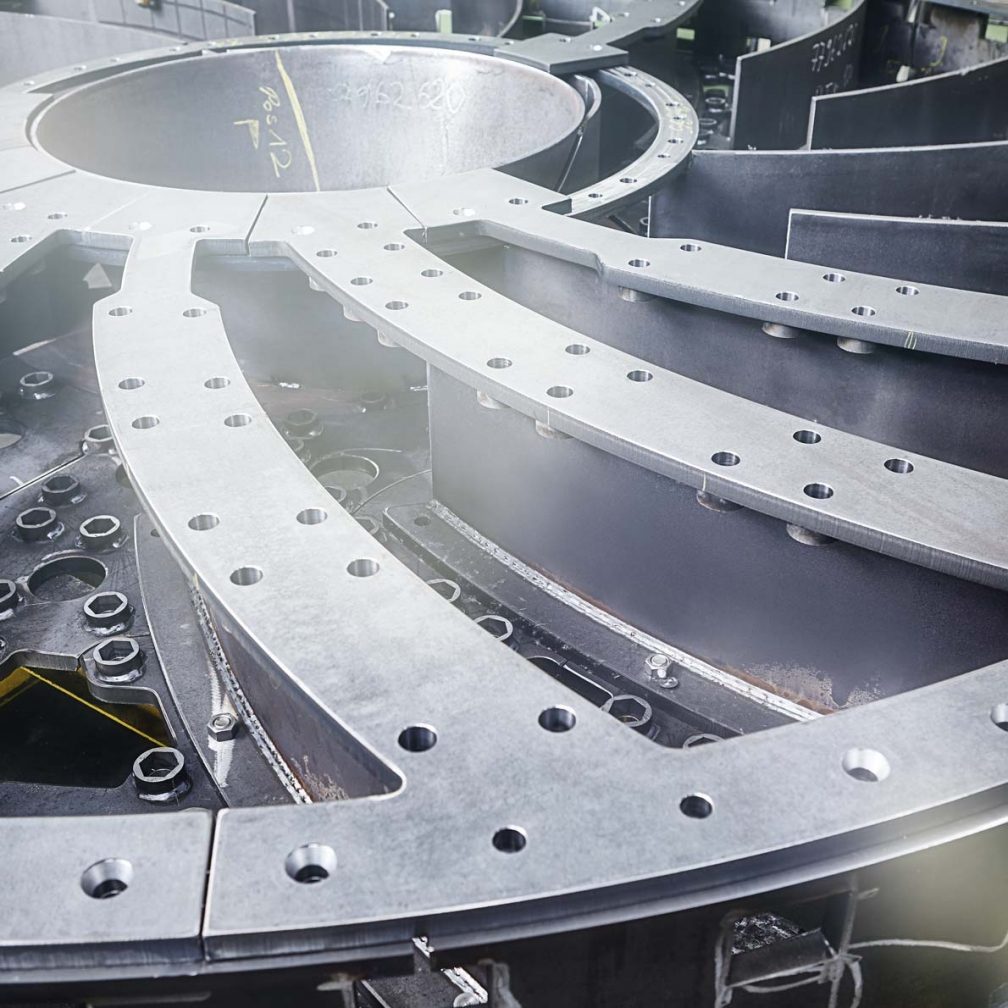

sorter

Grinding ball sorting machine

Grinding balls such as the Allmax® grinding balls are extremely robust and have a long service life. With a grinding ball sorting machine by Christian Pfeiffer, their use becomes even more efficient. After passing through the sorting machine, the grinding balls can be examined in detail. Afterwards, they can be reused or replaced with new ones depending on wear.

pROtector

Effectively protects the separator

The foreign material trap catches scrap particles and other foreign material such as deformed or broken grinding balls, preventing them from returning to the grinding process. The classifier is effectively protected from damage by foreign material.

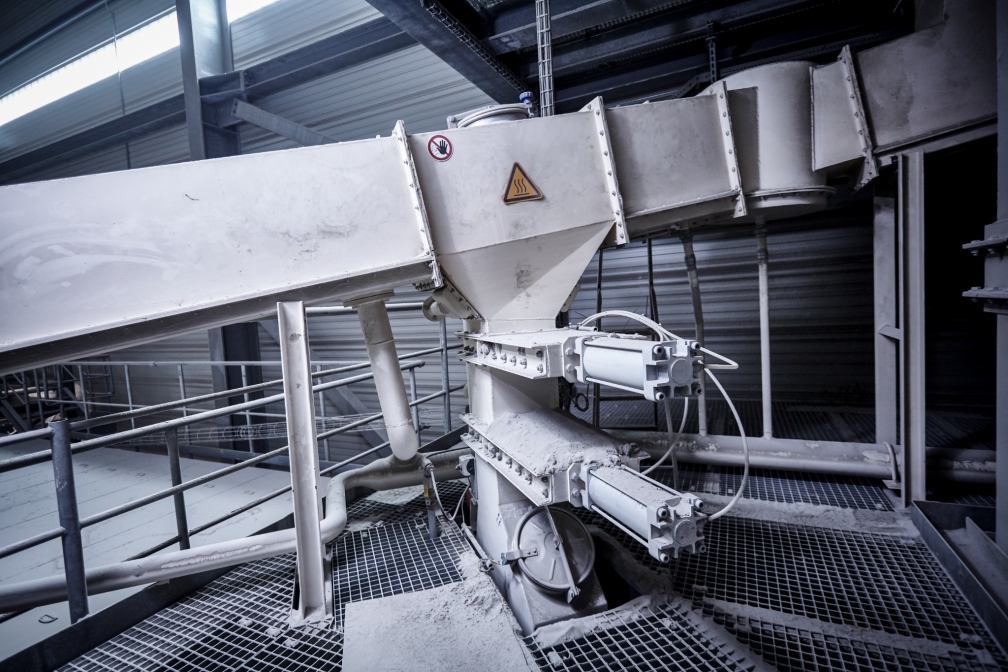

injector

Control the temperature during the grinding process.

When grinding minerals (materials) in a ball mill, a large proportion of the electrical energy required is converted into grinding heat, which can cause problems with the material properties or later in the process. Water injection is the simplest and most effective way to control the grinding temperature in the mill.

"The optimum material temperature ensures an ideal product flow. The more homogeneously the material can flow, the less energy is required."

Hendrik KruseHead of Competence Centre

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.