Increase of

product quality

with the cooler

Reduce product temperature and increase quality

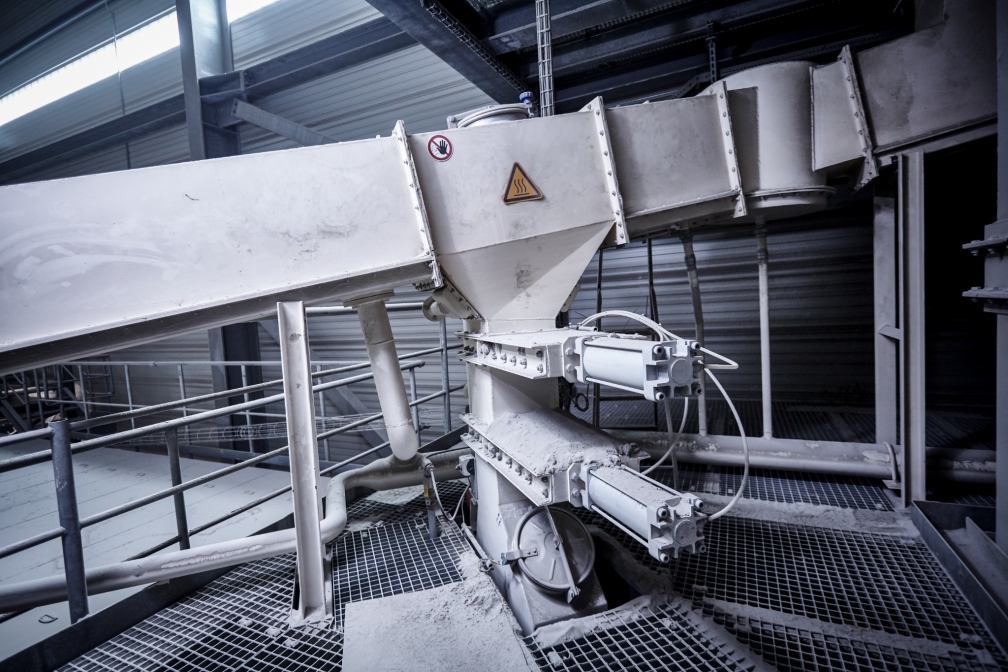

In order to improve general or specific product quality it is often necessary to cool the finished product directly after grinding. A powder cooler by Christian Pfeiffer provides the right solution for this task. It is suitable for all powder products, grits, and circulating material from grinding plants or similar production processes.

Technical details

- Indirect heat removal using the counterflow principle: The material to be cooled has no contact with the heat removal medium

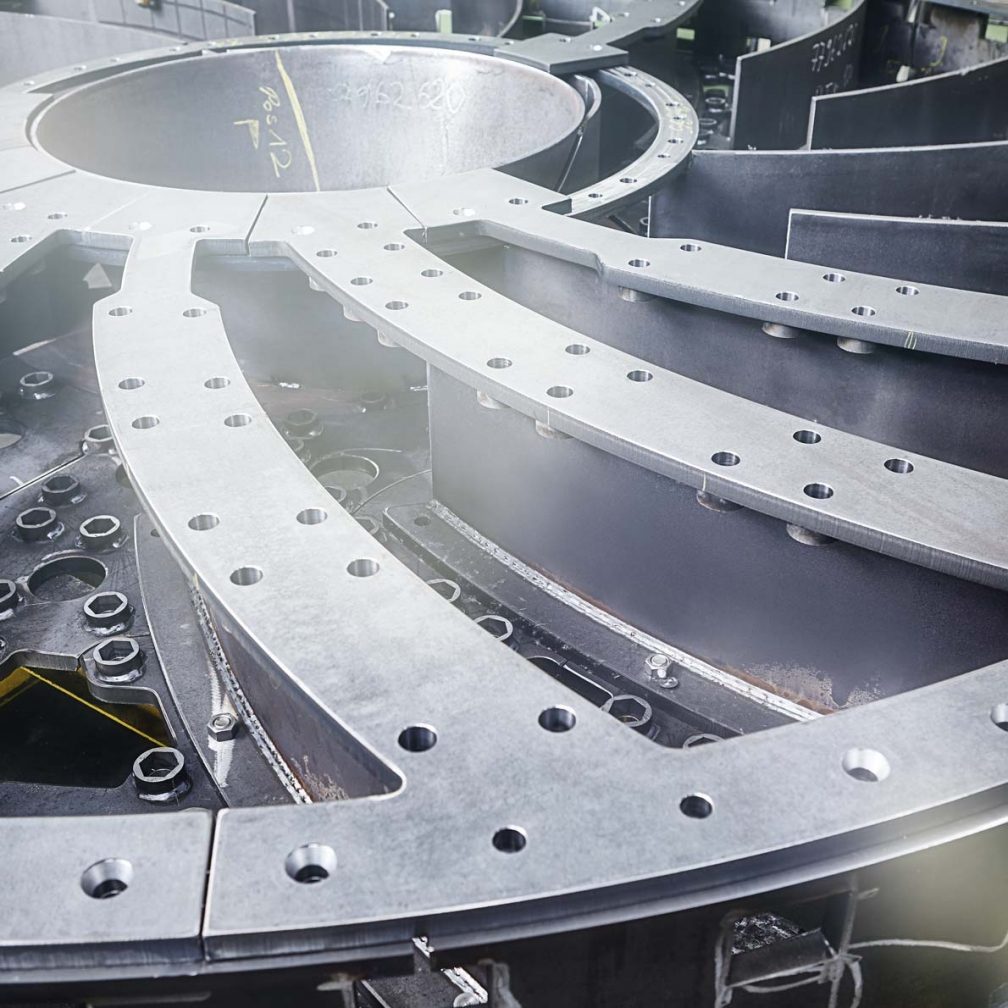

- Continuous and careful heat removal by means of an inside rotor that moves the material to be cooled upwards

- The temperature of the input material can be reduced by 40°C to 70°C

- If required, the cooling water can be returned to the cooling circuit using a recooling system

- A water film cools the steel cylinder from the outside

- Three machine sizes enable material throughputs of up to 180 t/h

- Their compact design enables trouble-free installation in new plants, as well as easy integration into existing systems

- Christian Pfeiffer's engineers conduct a water analysis and determine the plant components that will be required

Can powder coolers be integrated in existing plants?

Yes, in most cases, retrofitting in existing plants is possible without any problems. The powder cooler is arranged vertically, in consequence the material inlet takes place in the lower area, the powder is conveyed upwards by a screw in the cooler, and from there it is returned to its original transport path.

Of which components does a powder cooling system consist?

A powder cooling plant consists of two components, the cooling tower and the required water supply. The water supply can be a continuous flow system or the COOLER is connected to existing water cooling systems in the plant. Alternatively, we can also supply a separate water recooling system with water treatment, which is supplied with moderate amounts of water.

How much can the product temperature be reduced?

In most cases, a temperature reduction of about 50°C is feasible. Usually, our customers ask for cooling of fine powdery products from 110-120°C down to 65-70°C.

However, the temperature to which the product can be cooled down depends on various conditions.If the material is to be cooled down even further, a series connection of two coolers can be useful.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.