Reliable equipment for the mining industry

highest demands, toughest conditions, coarsest materials, maximum operational safety

For optimum grinding results with maximum operational reliability, we combine expertise at many levels. In the field of engineering, we attach great importance to the design of efficient, robust components. Mills, tanks, pumps and hydrocyclones are manufactured and supplied by us and specifically matched and documented for your processes. The quality of our products ensures the quality of your products, we are aware of that. That is why our customers also receive detailed technical documents, because we stand by our word.

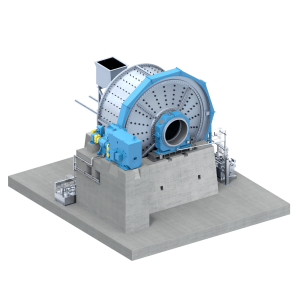

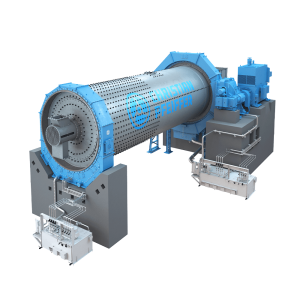

Reference project in record time. In Aljustrel, Portugal, we have erected a new ball mill first grinding stage for Almina - Minas do Alentejo, S.A. The mill with ø 4.2 m (330 tph of abrasive ores with trace materials such as pyrite and quartz) was engineered and delivered within 6 months. Commissioning was carried out with minimum downtime. Projects in the mining sector were implemented worldwide, including South Africa, Russia and Greece.

reliable products for the mining industry

SAM autogenious and semi-autogenious mills

Durable and reliable mills for toughest conditions.

Ball mills BAM

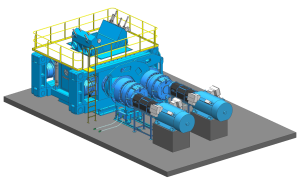

ROP Rollerpress

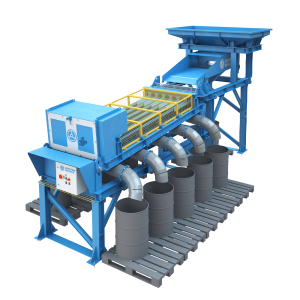

The SORTER

The sorter classifies reliably the grinding balls according to their size. Broken balls are sorted out.

Hallett Construction Materials assigns Christian Pfeiffer

Hallett Construction Materials assigns Christian Pfeiffer with a sustainable ball mill grinding circuit for its Green Cement Manufacturing plant located in Port Augusta, South AustraliaProjectsNews

Official dissociation from the cover advertisement of the Russian cement journal "Cement and it's applications".

CementCompany

Hard shell - flexible core: the unique Christian Pfeiffer FLEXCORE technology plates for 100% guaranteed durability

When a single plate in an intermediate diaphragm breaks, grinding balls get into the inner construct of the diaphragm and can destroy it immediately – a worst case scenario.CementR&DService

“We're super grateful for your feedback! It keeps us on our toes, making sure we're always giving you the best service possible. Together, we make awesome success stories happen, and we're pumped to be a part of your journey. For instance, we were thrilled to receive the following testimonial: 'Our vision is to be fulfilled through the continuous improvement of processes and the support of our customers and suppliers. […] Christian Pfeiffer demonstrated great flexibility and proved to be a reliable partner in all matters.' Thank you very much for the professional partnerships you build with us."

Francisco CanepaHead of Sales

more than

100 ball mill

installations worldwide

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.