Precise separators

for every need

our separators for every need

From our high efficiency separators, through to the all-in-one aggregate Heyd Separator : Christian Pfeiffer offers you a variety of separators to meet the special demands of your production lines.

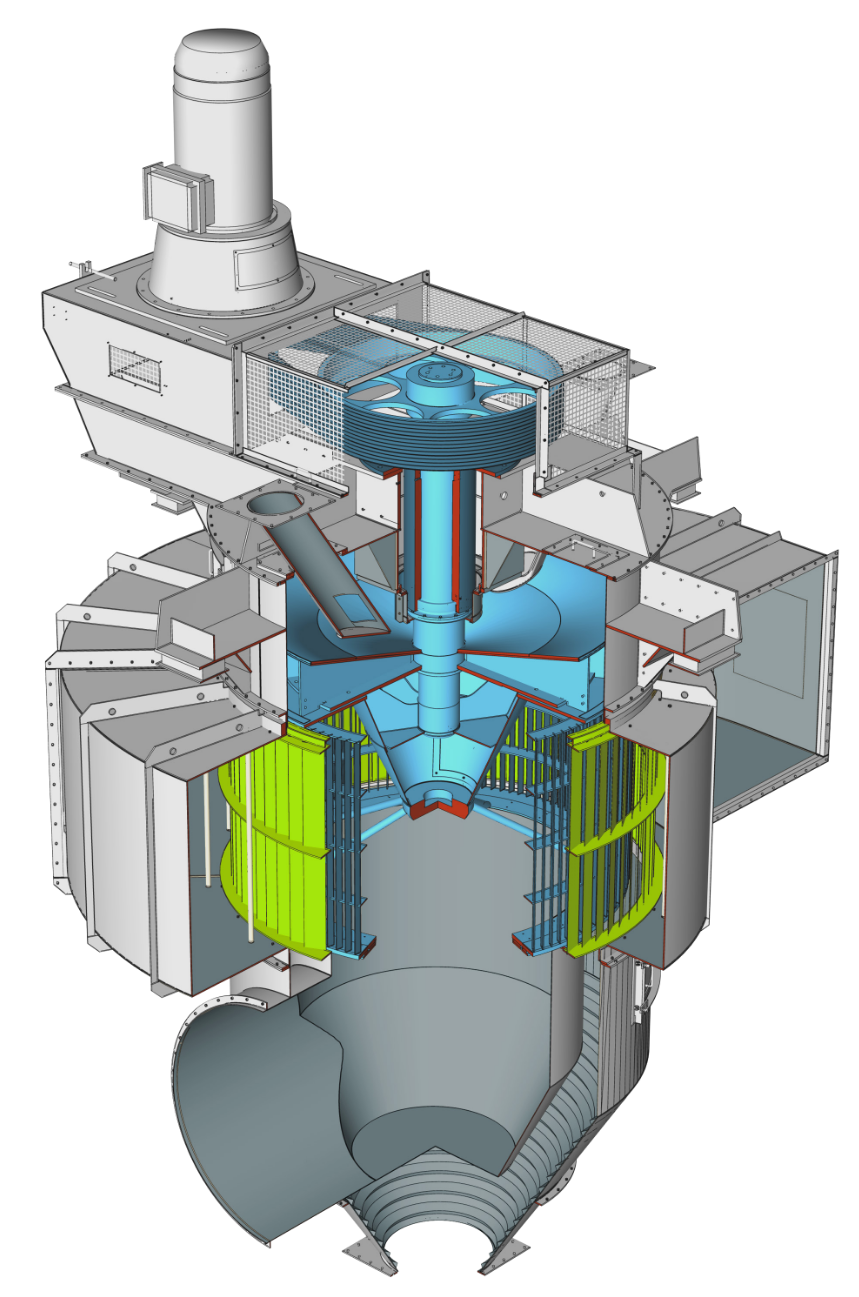

technical advantages of qdk

In contrast to its competitors, the QDK does not have a gearbox that requires maintenance. The V-belt is comparatively very low-maintenance and, unlike the gear unit, does not require lubricant.

It ensures that the bearings remain dust-free. The „flying“ bearing is extremely maintenance-friendly and low-wear. It can be removed comparatively easily and ensures high availability and operational reliability. Other separator models have a fixed bearing that restricts the rotating cage above and below. This has the disadvantage that one of the two bearings is exposed to the dusty air and thus wears out more quickly.

In all separator models, the rotary cage must be sealed in the direction of the finest discharge so that the coarse material does not mix again with the fine material that is sucked through the rotary cage. Labyrinth seals are often provided for this purpose, which again wear out and have to be replaced. Christian Pfeiffer, on the other hand, loosens the seal by means of sealing air, which blows out the interspace and prevents coarse material from mixing with the fine material again.

In contrast to its competitors, the QDK does not have a gearbox that requires maintenance. The V-belt is comparatively very low-maintenance and, unlike the gear unit, does not require lubricant.

It ensures that the bearings remain dust-free. The „flying“ bearing is extremely maintenance-friendly and low-wear. It can be removed comparatively easily and ensures high availability and operational reliability. Other separator models have a fixed bearing that restricts the rotating cage above and below. This has the disadvantage that one of the two bearings is exposed to the dusty air and thus wears out more quickly.

In all separator models, the rotary cage must be sealed in the direction of the finest discharge so that the coarse material does not mix again with the fine material that is sucked through the rotary cage. Labyrinth seals are often provided for this purpose, which again wear out and have to be replaced. Christian Pfeiffer, on the other hand, loosens the seal by means of sealing air, which blows out the interspace and prevents coarse material from mixing with the fine material again.

QDK

one separator for every need

It is no surprise that the proven QDK high efficiency separator is the most popular product of our range of separators. The standard version of the cross-flow rotating cage separator can be integrated into almost any grinding plant. Top cuts of up to 10 µm can be produced, thanks to the particularly constant separating conditions within the entire separating zone.

ROC

The expert for very fine products

Our clients demand higher material purity, top cuts of D98 = 3 – 100 µm, greater performance, low energy consumption, and affordability. With all of that in mind we developed the fine classifier ROC. ROC is not only a reflection of our vast experience but is the answer and go to solution for fine mineral classification.

u-roc

for ultra-fine results

When fine is not fine enough. We can achieve ultra-fine results with top cuts down to d98<3 µm with our U-ROC classifier.

U-ROC was developed with a challenge in mind of being able to classify ultra-fine materials keeping high performance. The efficiency that this classifier delivers is mature, even running at speeds above 4000rpm.

QDK-T

The space saver

The compact design of our Top Gas Separator QDK-T allows particularly flexible installation, and demonstrates its advantages especially when modernizing existing plants. With a top cut of up to 10 µm, it is installed instead of a QDK separator in plant layouts where space is an issue.

QDK-l

the pro for raw meal and coke

The dynamic airflow separator QDK-L is used in airflow mills, and is primarily used in grinding petcoke or coal, as well as raw meal. Depending on the material to be ground, it can also be used to separate other products, such as minerals, limestone, feldspar, or quartz sand. The input material enters the QDK-lL with the separator airflow from below, and is sucked upwards into the separator by the airflow. It provides a top cut of up to 20 µm.

fix and qdk-f

a great team

For combined roller press and ball mill grinding systems. The QDK-F is a dynamic separator working together with the static separator FIX. The material enters the QDK-F through two feeding points: an airflow and two feeding chutes above the separator. The QDK-F provides a top cut of up to 20 µm.

QDK-m

for dry products in vertical mills

The dynamic mineral separator is specifically designed for the use with vertical mills, and is suitable for the separation of products with relatively little moisture, e.g. the grinding of minerals. The QDK-M is fed from below, and supplies a top cut of up to 20 µm.

qdk-k

for damp materials in vertical mills

The dynamic coal separator QDK-K is used in cases where materials with high feed moisture are ground. The vertical position of its centrally-positioned feeding chute prevents the damp material from sticking. The material to be ground thus goes directly to the grinding table of the vertical mill. The DSK is often used for the separation of coal or petcoke, and provides a top cut of up to 20 µm.

heyd separator

the universal talent

With a top cut of between approximately 60 µm and 200 µm the Heyd separator improves the quality of the final product enormously. The Heyd separator is an all-in-one aggregate – thus neither cyclones or filters to discharge finish product, nor a process ventilator are required. An integrated adjustable fan wheel and reverse flow blades ensure optimum finish product output.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.