U-ROC

finest

classifying

the finest results in classifying

We can achieve ultra-fine results with top cuts down to d98<3 µm with our U-ROC classifier.

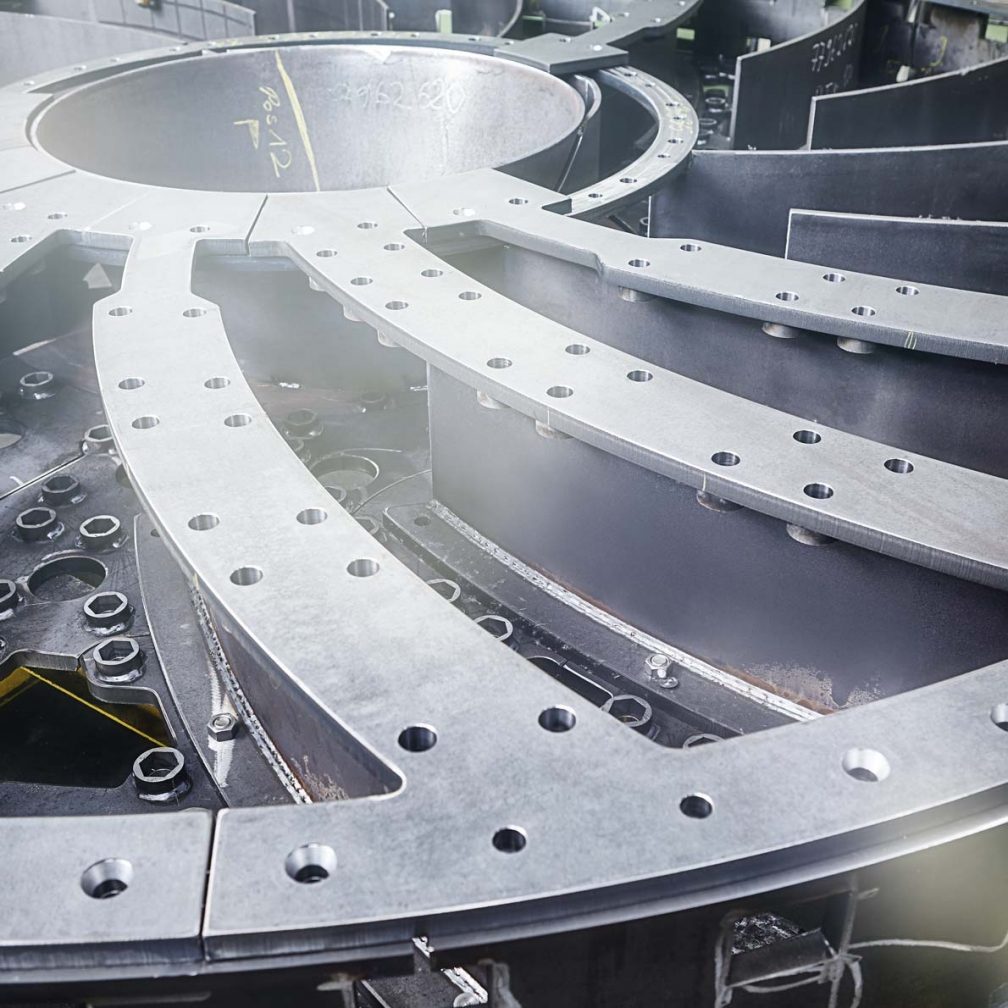

U-ROC was developed to face the challenge of being able to classify ultra-fine materials while keeping high performance. The efficiency that this classifier delivers is outstanding, even running at speeds above 4000rpm.

Technische Details

- The dual fines discharge achieves equal classification air speed across the whole rotor length with minimal drop in pressure.

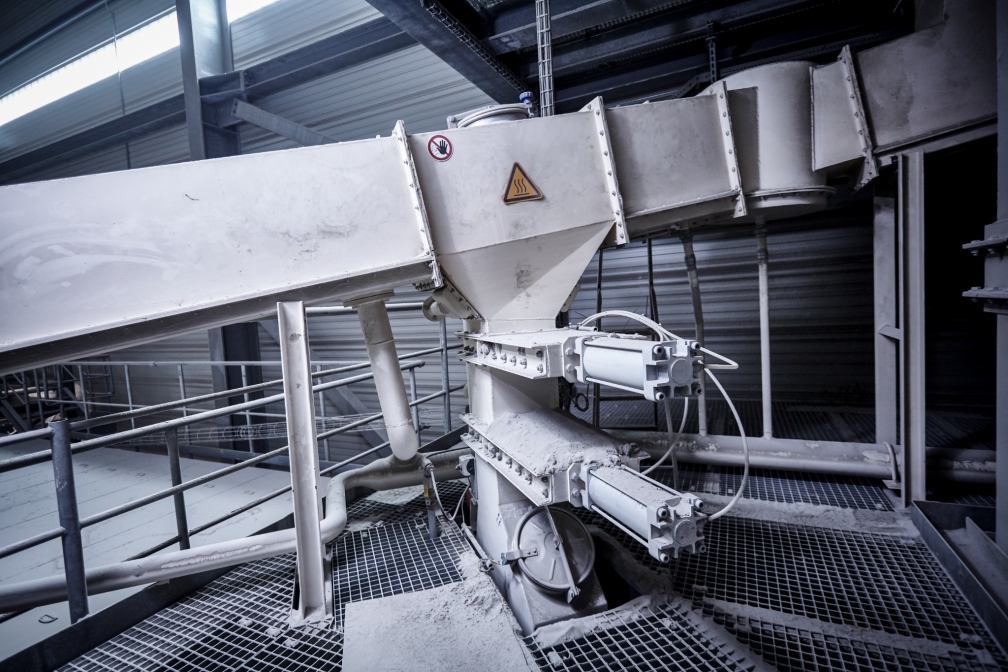

- The material is fed pneumatically directly into the separation area, creating maximum dispersion for a more homogeneous classification

- A secondary air inlet allows for process optimization by the reclassification of rejects, increasing efficiency.

- The rotor gap sealing air, allows to achieve a clean top-cut (5ppm at 25µm) and a maintenance free operation.

more than 1,000 installations worldwide

What is the function of a separator?

The separator classifies the material stream into two partial streams depending on the particle size. The separator is charged with powdered material, consisting of particles of different sizes, in a continuous process. It defines the finer particles as the finish product by selecting them from the feed material. The rejected coarse particles and the non-selected fine particles are fed out of the separator as a second mass flow.

What is the function of the jalousy ring in classifiers with a rotating basket?

The jalousy ring serves as a static pre-classification device to define the amount of material passing to the rotating cage. At the same time, it limits the space around the rotating cage which makes it easier to adjust the flow conditions.

What does the term "loading factors" mean?

We often talk about two loading factors with regards to the separator. The feed loading and the fines loading in [kg/m³]. It means the mass of the respective fraction per air volume.

The higher the permissible loading factors, the smaller the separator can be designed to classify the required tonnages. Permissible loading factors mean the lowest value under which a separator can still effectively and reliably fulfill its function. Coarse material loading is not relevant in this context because it has no influence on the functionality of the separator.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.