Helping you achieve your climate goals.

With the highest efficiency in cement grinding.

That is our mission every day. Because we don’t just want to keep pace, we want to move ahead, to make a contribution to shaping the cement industry with our ideas. We do that by constantly improving our:

Mill inspection app

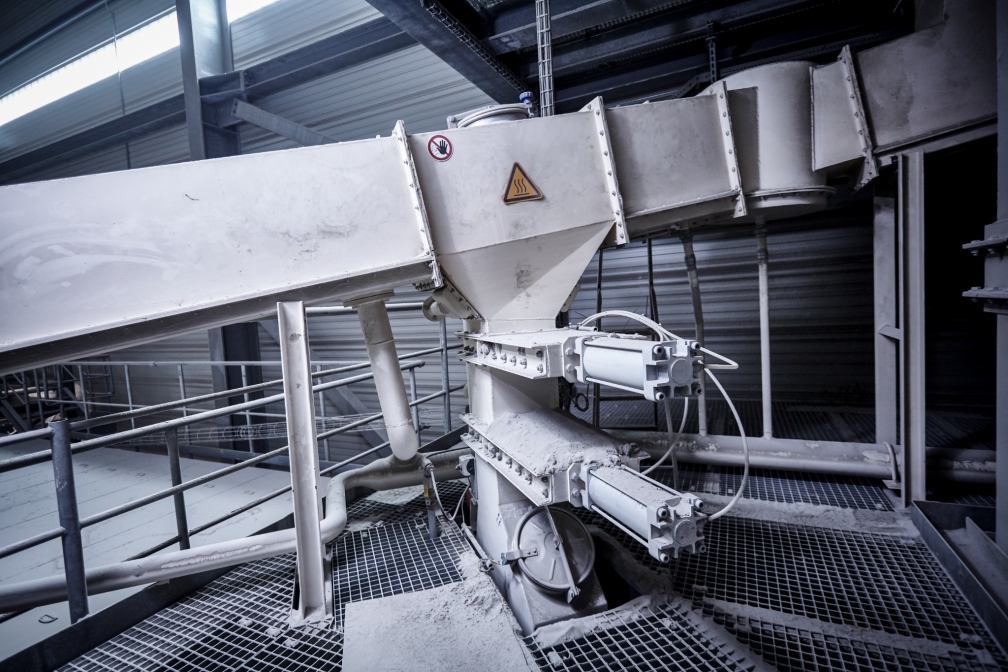

The Christian Pfeiffer Mill Inspection App helps users to ensure that the grinding plant

is operating as energy-efficiently as possible.

"When small alterations make a big difference in energy efficiency, we need to understand the importance of every detail in the process."

Dipl. Ing. Tim NowackHead of process and R&D

How our grinding plants are tailored to the requirements of the cement industry:

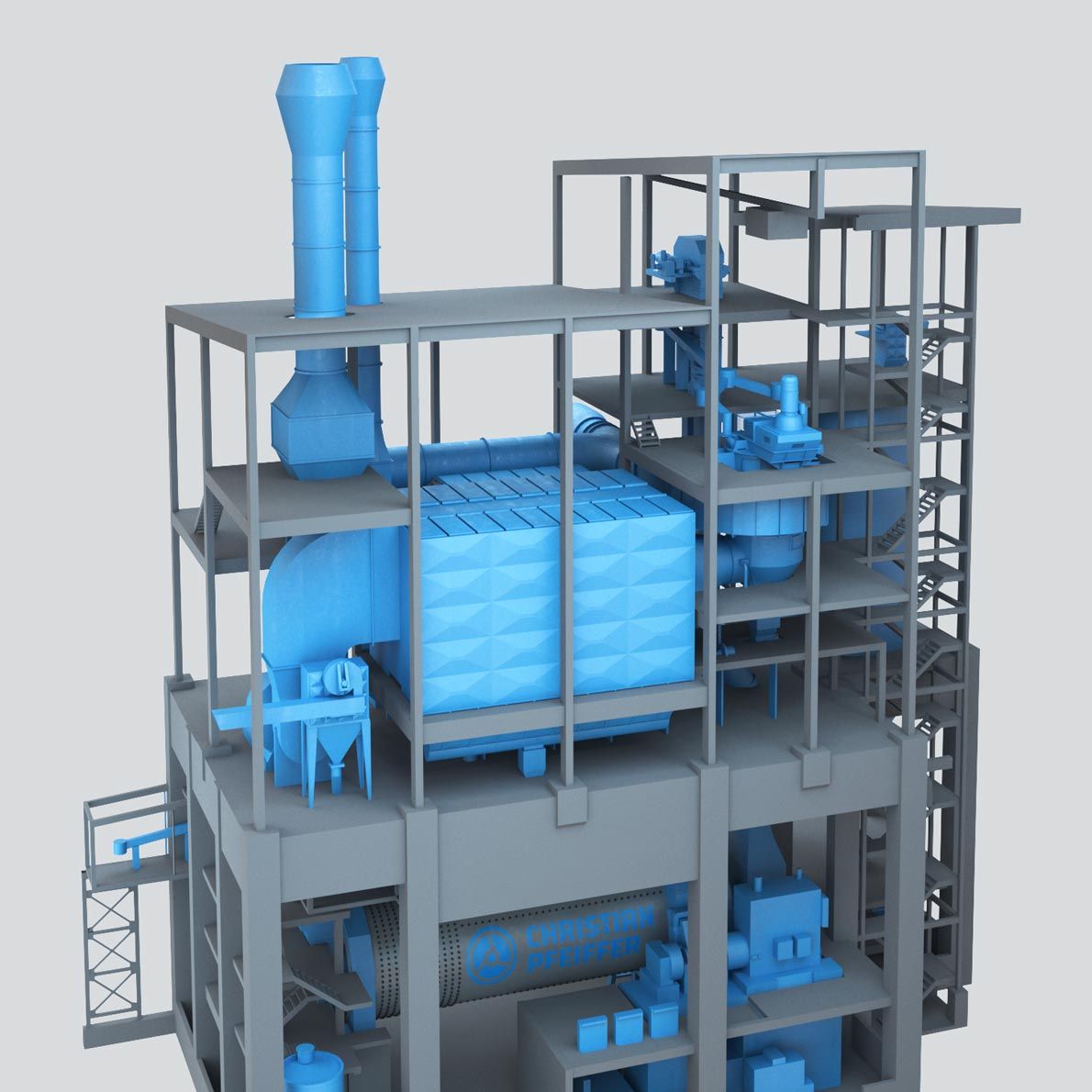

Boosts production capacity, energy efficiency and product quality.

Meet the highest demands in terms of energy efficiency, service life and operational reliability.

Intelligent plant design by Christian Pfeiffer to save maximum energy and space.

Components that we choose for plants match our comprehension regarding quality, energy efficiency and project management.

Boosts production capacity, energy efficiency and product quality.

Meet the highest demands in terms of energy efficiency, service life and operational reliability.

Intelligent plant design by Christian Pfeiffer to save maximum energy and space.

Components that we choose for plants match our comprehension regarding quality, energy efficiency and project management.

more than

100 ball mill

installations worldwide

Hallett Construction Materials assigns Christian Pfeiffer

Hallett Construction Materials assigns Christian Pfeiffer with a sustainable ball mill grinding circuit for its Green Cement Manufacturing plant located in Port Augusta, South AustraliaProjectsNews

Official dissociation from the cover advertisement of the Russian cement journal "Cement and it's applications".

CementCompany

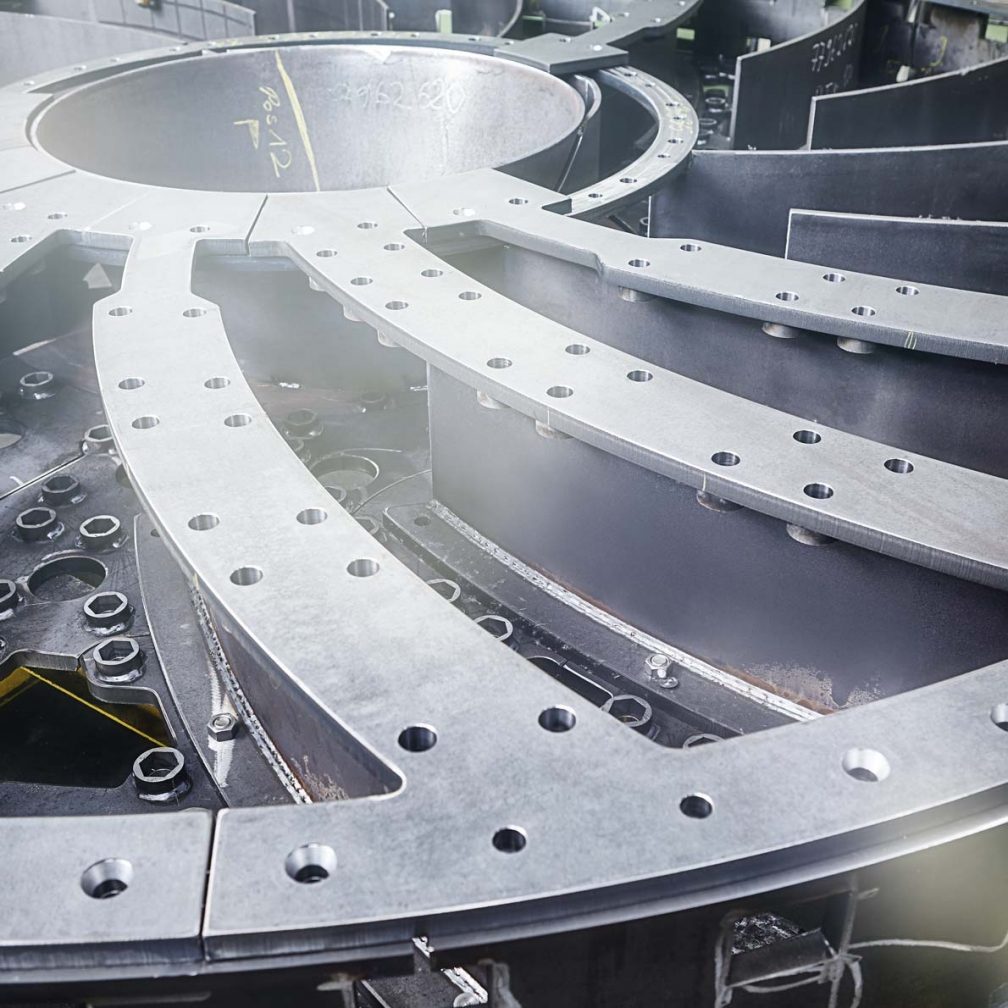

Hard shell - flexible core: the unique Christian Pfeiffer FLEXCORE technology plates for 100% guaranteed durability

When a single plate in an intermediate diaphragm breaks, grinding balls get into the inner construct of the diaphragm and can destroy it immediately – a worst case scenario.CementR&DService

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

"We understand that service is not only the installation of plants or equipment and to keep it running. Our technical service department is at your side, helping with any problem at every step of the process."

Detlef EnseleitHead of Technichal Service and Production

Fine cement: Higher strength with lower energy?

Mill considerations when grinding finer cement. Most mill circuits are presently not designed to produce fine cements effectively. We know how small alterations can reduce the negative impact.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.