We are the experts for the

most efficient grinding processes.

NOW and in the future.

We grind it all.

Whatever the material or the challenge is we find a solution. Because that is what we do everyday for nearly a century. Solutions that create perfect results shape a whole industry.

USE THE ROI CALCULATOR FOR CHRISTIAN PFEIFFER DIAPHRAGMS

What do you need to grind?

THE ORIGINAL CHRISTIAN PFEIFFER

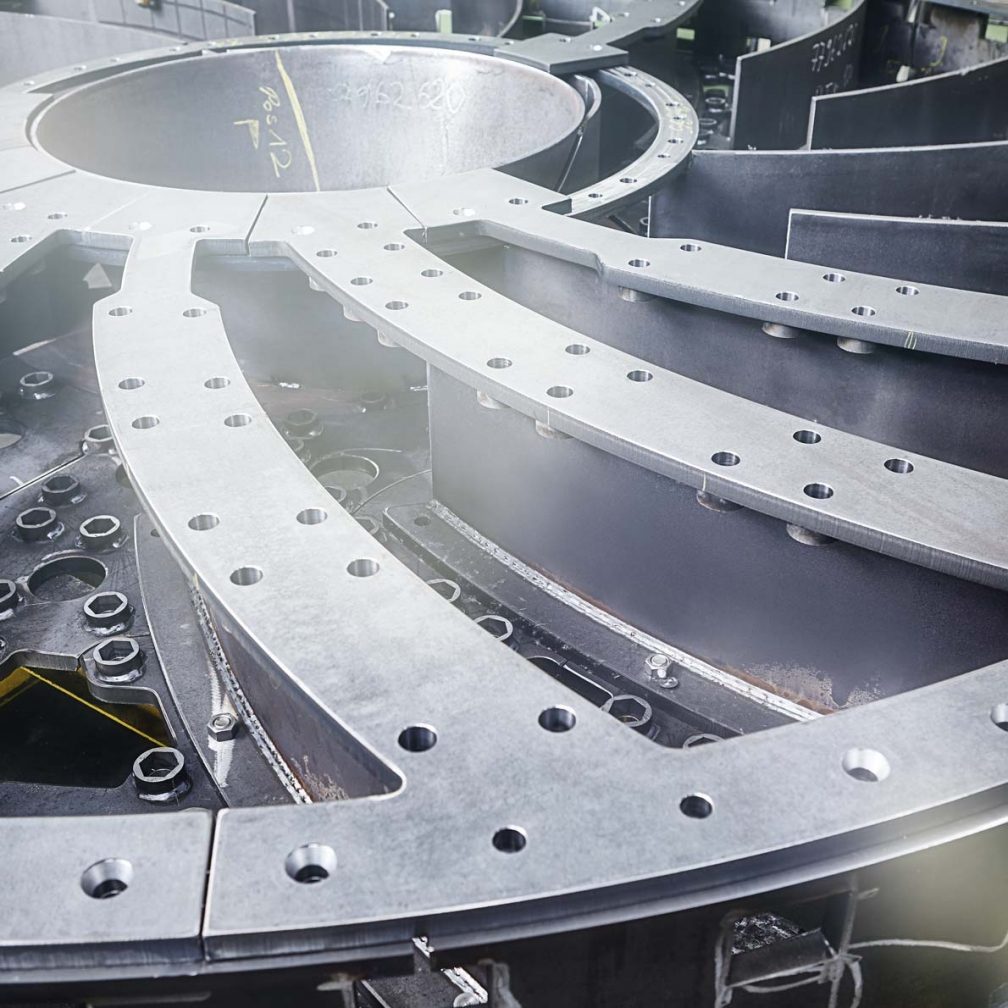

FLEXCORE TECHNOLOGY

Grinding plant specialist Christian Pfeiffer developed the high-performance and reliable FLEXCORE technology plates. Unique and special: they are made of hardened rolled steel with up to 60 HRC due to a very hard shell and gradually softer material towards the core.

Mill inspection app

The Christian Pfeiffer Mill Inspection App helps users to ensure that the grinding plant

is operating as energy-efficiently as possible.

Hallett Construction Materials assigns Christian Pfeiffer

Hallett Construction Materials assigns Christian Pfeiffer with a sustainable ball mill grinding circuit for its Green Cement Manufacturing plant located in Port Augusta, South AustraliaProjectsNews

Official dissociation from the cover advertisement of the Russian cement journal "Cement and it's applications".

CementCompany

Hard shell - flexible core: the unique Christian Pfeiffer FLEXCORE technology plates for 100% guaranteed durability

When a single plate in an intermediate diaphragm breaks, grinding balls get into the inner construct of the diaphragm and can destroy it immediately – a worst case scenario.CementR&DService

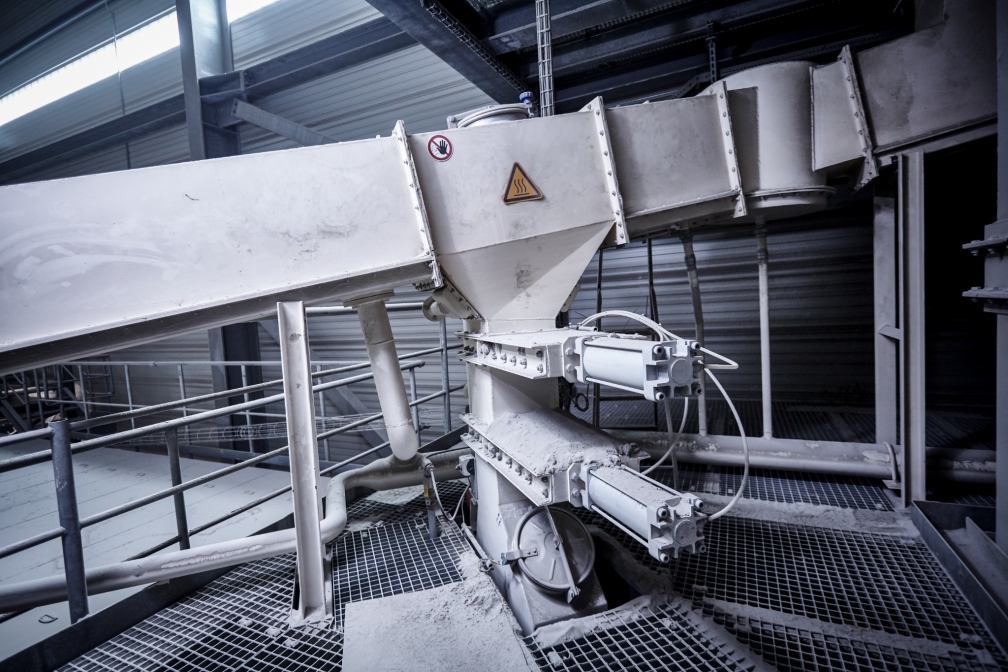

Our efficient grinding plants are tailored to TOday's requirements

“We're super grateful for your feedback! It keeps us on our toes, making sure we're always giving you the best service possible. Together, we make awesome success stories happen, and we're pumped to be a part of your journey. For instance, we were thrilled to receive the following testimonial: 'Our vision is to be fulfilled through the continuous improvement of processes and the support of our customers and suppliers. […] Christian Pfeiffer demonstrated great flexibility and proved to be a reliable partner in all matters.' Thank you very much for the professional partnerships you build with us."

Francisco CanepaHead of Sales

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.

Ask our Experts

Do you have a specific challenge or just a quick request? Get in touch: