an overview of our products

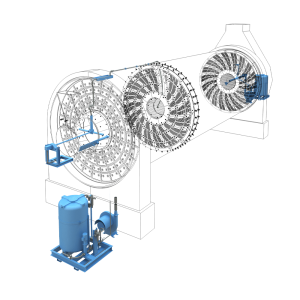

We design and build grinding plants and equip them with all the right features or auxiliaries. Our separators ensure even greater efficiency of your processes. And from the first idea to the last screw, we also design and build entire EP- or EPC-projects.

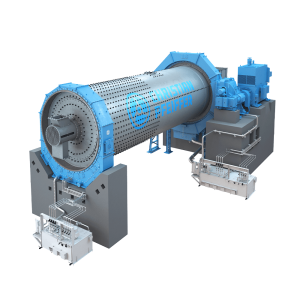

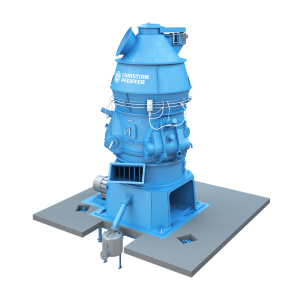

Mills

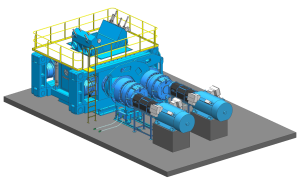

Ball mills BAM

ROP Rollerpress

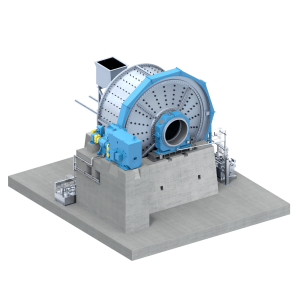

SAM autogenious and semi-autogenious mills

Durable and reliable mills for toughest conditions.

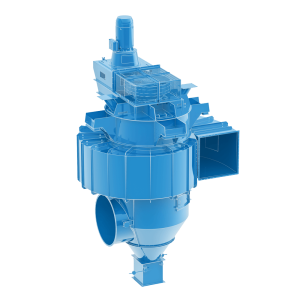

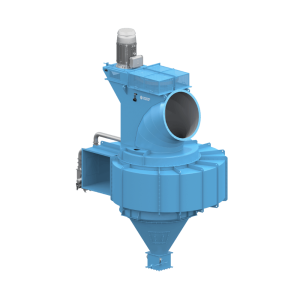

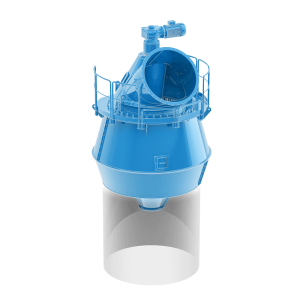

separators

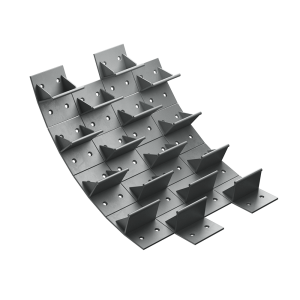

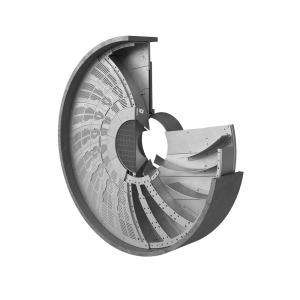

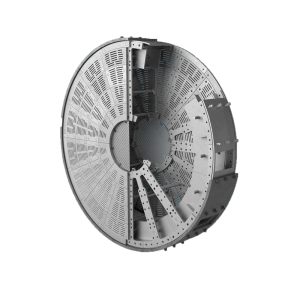

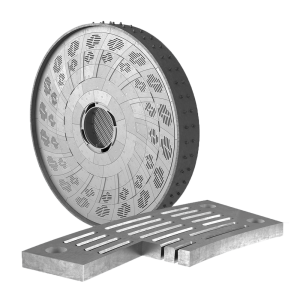

diaphragms

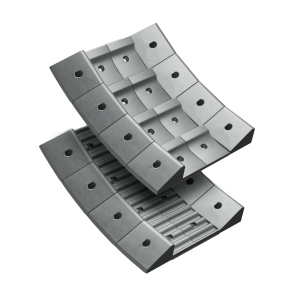

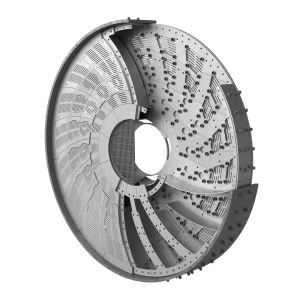

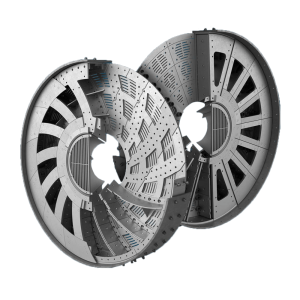

Intermediate diaphragm MONOBLOC

Open lifter diaphragm

Discharge diaphragm MONOBLOC

Double outlet diaphragm

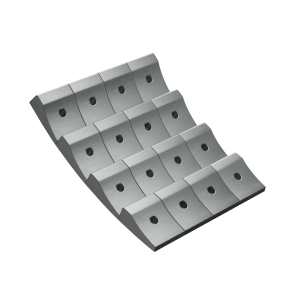

Slotted plates and backside plates

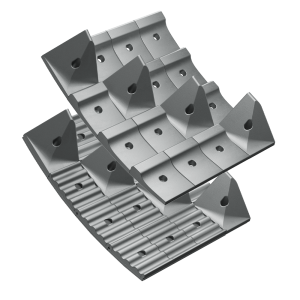

SHELL LINERS

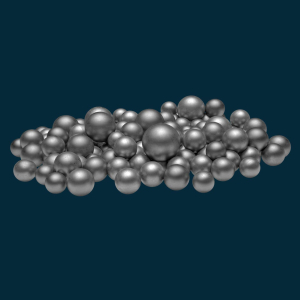

GRINDING BALLS

Complementary products

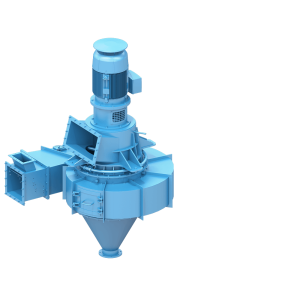

The COOLER

reduces the product temperature after processing and thus increases product quality.

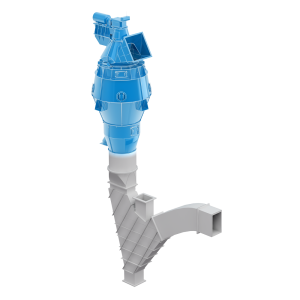

The INJECTOR

A water injection system is the easiest and most effective way to control the temperature during grinding in the mill.

The PROTECTOR

The foreign matter trap protector sorts out unwanted metal pieces while passing an airslide.

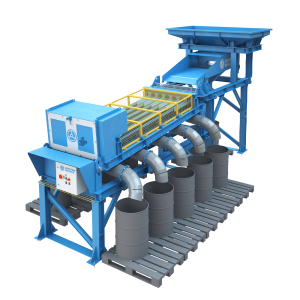

The SORTER

The sorter classifies reliably the grinding balls according to their size. Broken balls are sorted out.