Allmax®

Grinding balls

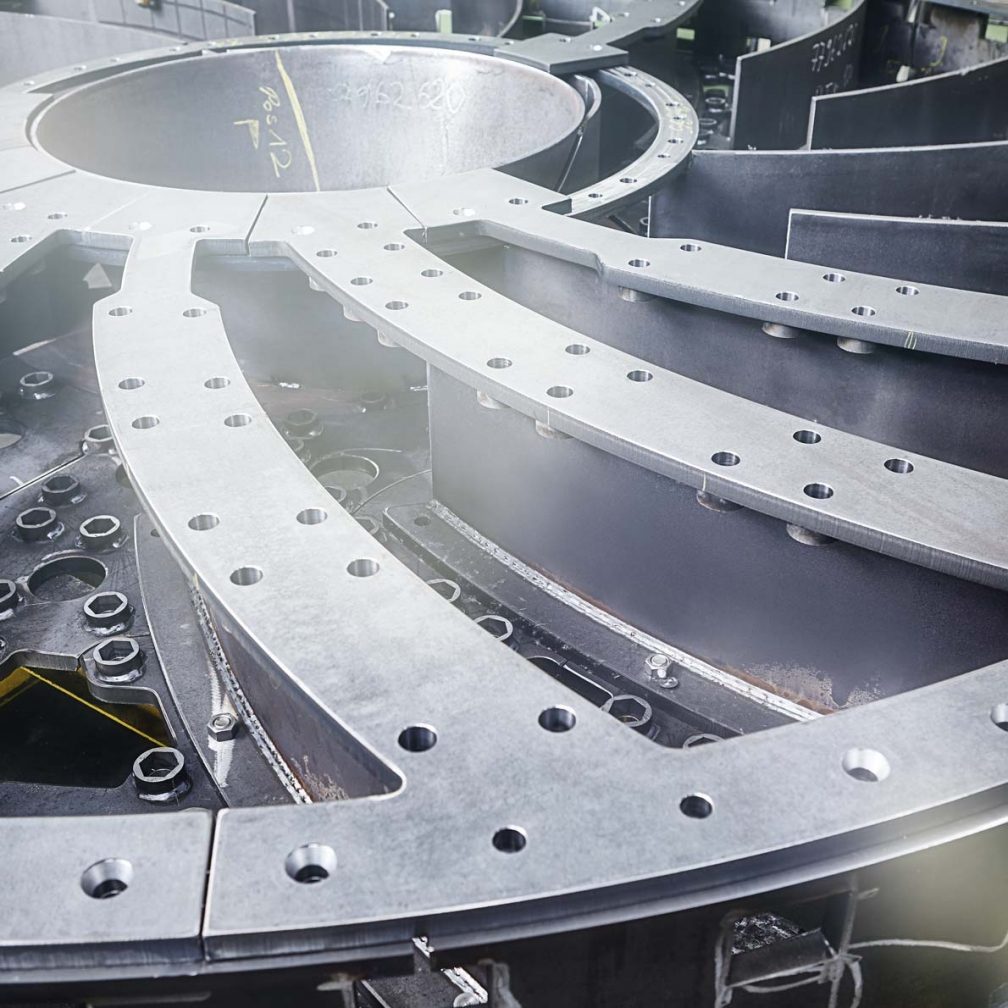

GRINDING BALLS MADE OF HIGH-ALLOY STEEL

The Allmax® grinding balls are extremely wear-resistant due to the use of high-alloy steel with 11% to 19% chromium content. Through years of research and development, the alloys have been optimally adapted to the requirements of the market.

Technical details

- Available sizes: from 17 to 100 mm diameter

- High hardness from 60 to 65 HRc

- Horizontal casting process as well as regular chemical and microscopic microscopic examinations guarantee fracture strength, a geometrically round shape, ideal microstructure, complete saturation in the section area and and a casting free of blowholes.

- Grinding ball Allmax I® (11-13% chromium content) is particularly suitable for cement grinding (raw material and clinker), in particular in the 2nd and 3rd chamber of a tube mill for cement and raw meal grinding

- Grinding ball Allmax II® (17-19% chromium content and higher) is particularly suitable for use in the 1st grinding chamber of a raw meal and cement mill

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

Our service

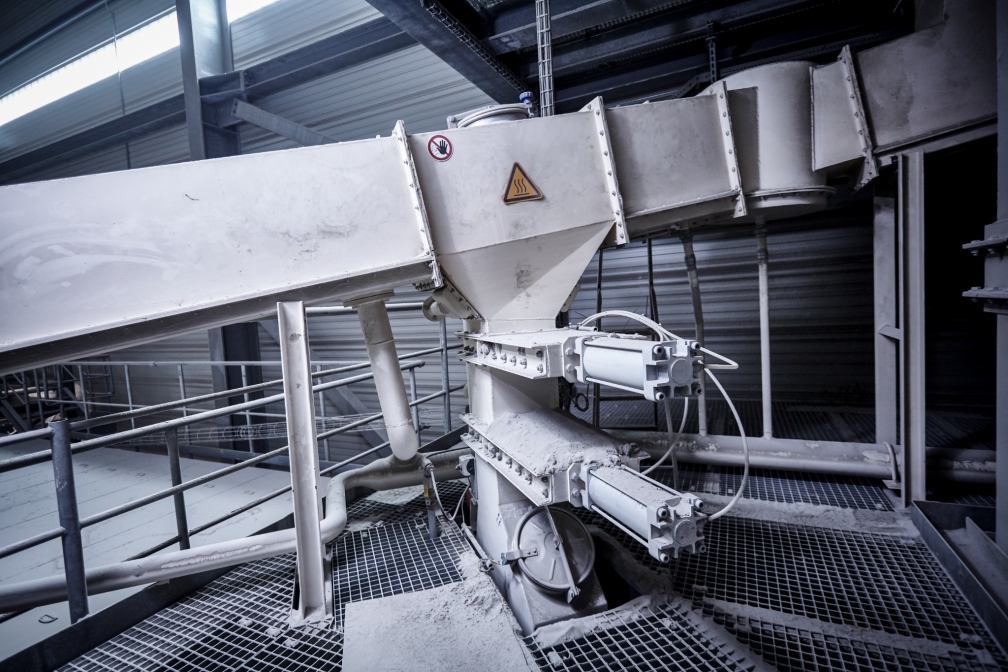

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

A story of efficiency

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.