High quality

diaphragms

MIll diaphragms With innovative

Monobloc design

Reduce energy consumption, increase efficiency: The installation of a diaphragm can increase the economic efficiency of a grinding plant enormously. The Monobloc® diaphragm developed by Christian Pfeiffer is highly stable, durable and particularly robust. According to the current state of the art, this type of diaphragm is considered the most sophisticated solution for modern grinding plants.

Advantages of the monobloc construction

Due to the material flow control and maximum particle size limitation of the diaphragm, the material remains in the first grinding chamber until optimum pre-comminution has been achieved and before passing into the second chamber.

The separation of air and material flow, a major development by Christian Pfeiffer, also ensures that so-called "dead zones" (zones without regrind) directly behind the diaphragm are avoided.

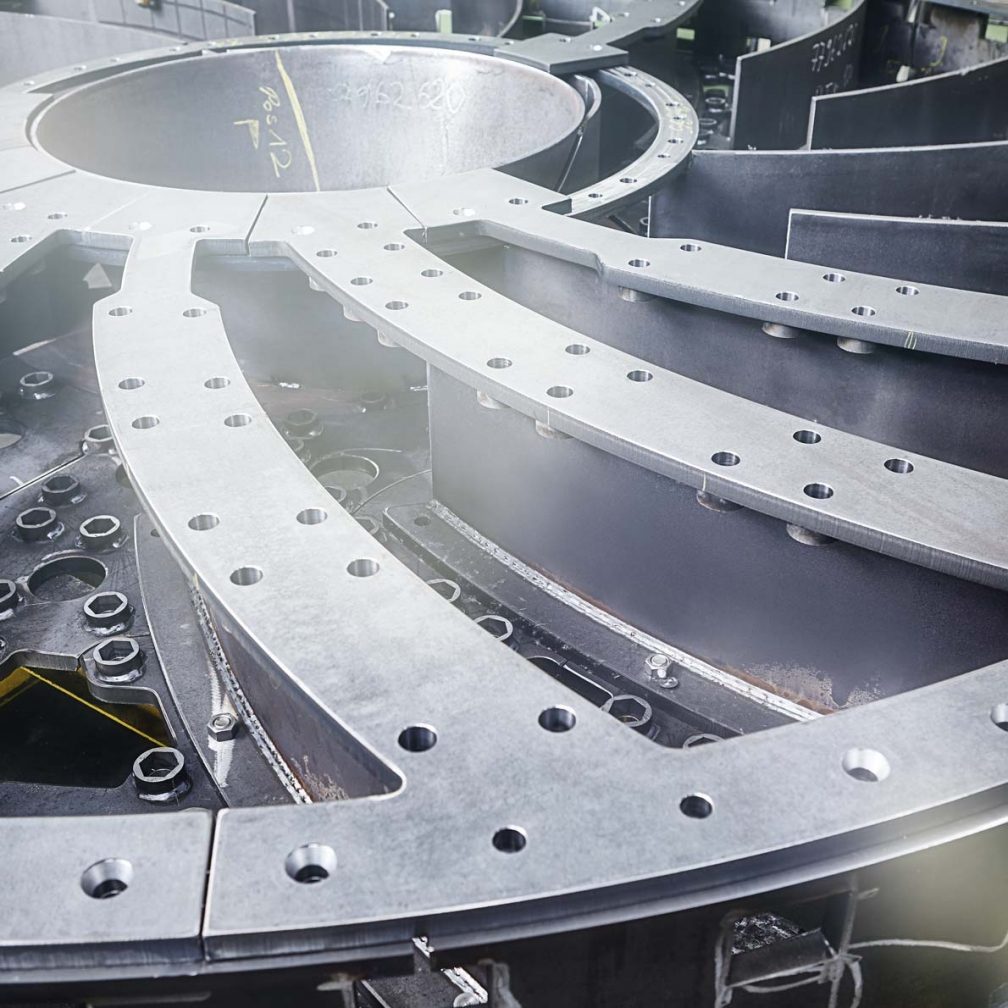

The structure of the Monobloc® diaphram design supports the mill cylinder and counteracts deformation. The individual parts of the diaphragm structure are welded to each other, making the diaphragm particularly stable.

The floating fixation reduces tension between the mill tube and the diaphragm structure.

Due to the material flow control and maximum particle size limitation of the diaphragm, the material remains in the first grinding chamber until optimum pre-comminution has been achieved and before passing into the second chamber.

The separation of air and material flow, a major development by Christian Pfeiffer, also ensures that so-called "dead zones" (zones without regrind) directly behind the diaphragm are avoided.

The structure of the Monobloc® diaphram design supports the mill cylinder and counteracts deformation. The individual parts of the diaphragm structure are welded to each other, making the diaphragm particularly stable.

The floating fixation reduces tension between the mill tube and the diaphragm structure.

USE THE ROI CALCULATOR FOR CHRISTIAN PFEIFFER DIAPHRAGMS

Intermediate diaphragm monobloc

Due to the material flow control and maximum particle size limitation of the transfer partition, the material to be ground remains in the first grinding chamber until optimal pre-shredding and only then enters the second chamber. The separation of air and material flow, a major development by Christian Pfeiffer, also ensures that so-called "dead zones" (zones without regrind) directly behind the mill wall are avoided. The result is a significantly more efficient grinding process.

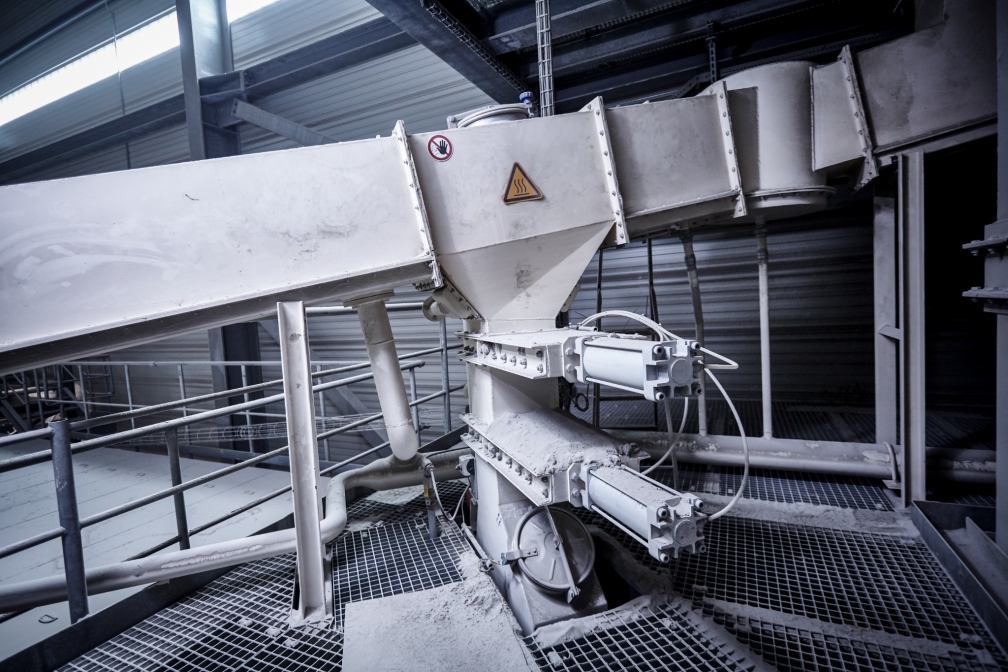

Discharge diaphragm

Individual adjustment to the grinding plant

The discharge diaphragm allows the ground material to pass, but retains the grinding balls in the grinding chamber. Christian Pfeiffer adjusts the diaphragm individually to the existing grinding plant, fixing it either on the discharge mill head or floating on the mill shell.

Open lifter diaphragm

For mills with integrated drying chamber

By means of the open lifter diaphragm, the drying chamber integrated into the mill tube is separated from the grinding compartment. The steel grades used can easily withstand the up to 400°C hot gases found in the drying compartment.

Double outlet diaphragm

For mills with central discharge

Mills with central discharge are fitted with a double outlet diaphragm. The material is transported from both head sides of the mill towards the diaphragm, then out through the openings in the mill shell.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.