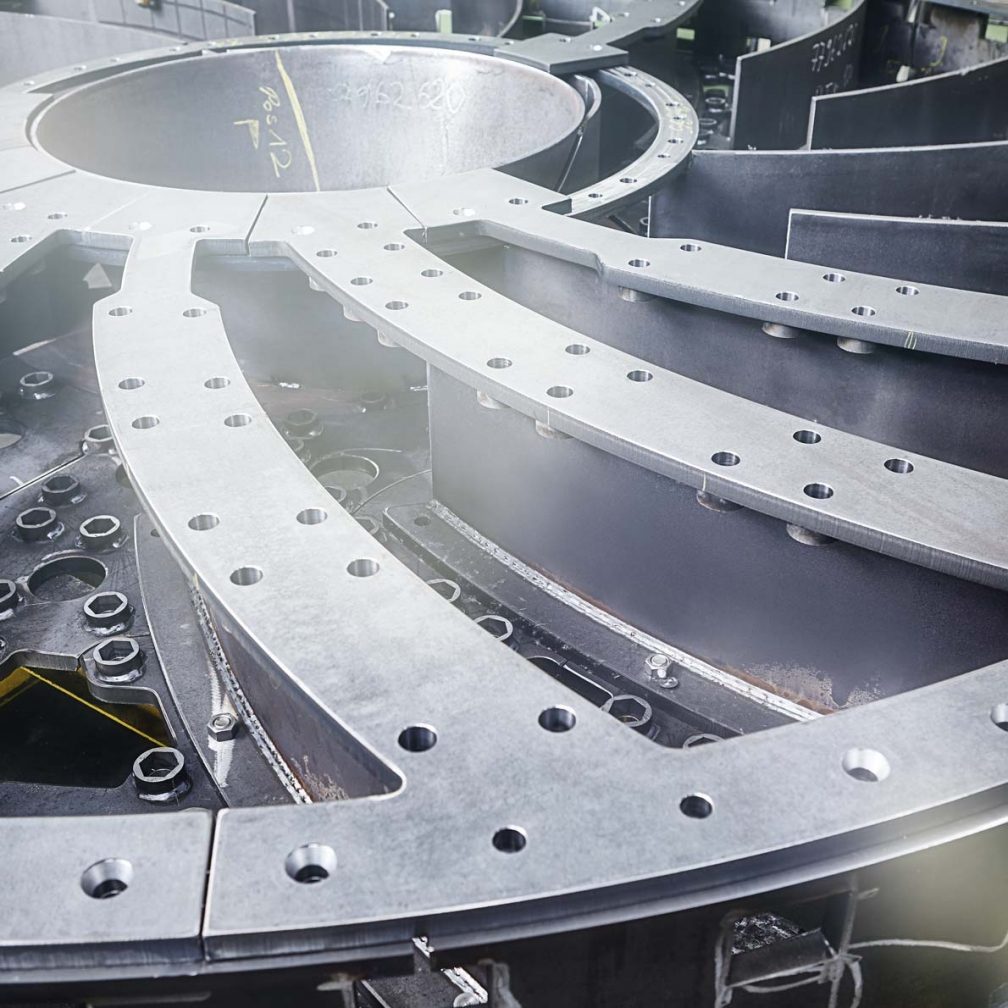

Open lifter

diaphragm

For mills with integrated drying chamber

By means of the open lifter diaphragm, the drying chamber integrated into the mill tube is separated from the grinding compartment. The steel grades used can easily withstand the up to 400°C hot gases found in the drying compartment.

Technical details

- Separation of grinding compartment and drying chamber integrated into the mill tube

- Use of steel grades with almost identical thermal expansion coefficients, in order to withstand the high temperatures (300–400°C) and high axial pressure

- Extremely high mechanical and thermal loads can be absorbed

- Adjustment of the diaphragm plates enables the adjustment of the central opening to the required maximum mill filling level

- Construction of the diaphragm in Monobloc® version: supports the mill tube and resists deformation. Can also be supplied in segmented design

- Easier maintenance and replacement of main wear zones through division of the slotted backside plates into two to four rings

more than 5,000 installations worldwide

How do diaphragms improve plant performance?

Modern diaphragms are designed to control the material flow and balance the material level in the first grinding chamber. The special feature of the Christian Pfeiffer intermediate diaphragms is that it directs the material into the second chamber separately from the air flow. This separation of material and air flow means that there is no unused zone behind the diaphragm. The material is fed directly into the second chamber at the backside of the diaphragm. As a result, the effective grinding length of the mill is fully utilized. In many cases, an increase in production of 3 - 6% can be achieved by the intermediate diaphragm MONOBLOC.

What is the average service life of a diaphragm?

The structure of a diaphragm has usually a service life of 10 years. Thanks to the Christian Pfeiffer MONOBLOC design and the floating connection, our diaphragms achieve significantly longer service lives in practice. The slotted and backside plates are replaceable wear parts that are highly dependent on the ground material.

According to the customer, the structure of the oldest Christian Pfeiffer diaphragm was in use in Latin America for 40 years.

What is meant by the self-cleaning effect of slotted plates?

The width and size of the slots define the material throughput and limit the maximum particle size that can pass the diaphragm. If the size reduction is insufficient, coarse particles get stuck in the slots of the diaphragm plates and become lodged. This reduces the throughput capacity and disrupts plant operation. It is therefore important to design the slots in such a way that material cannot get stuck permanently. Thanks to the circumferential slot arrangement and the milled groove for ball guidance, the cleaning effect by the grinding balls is very high. The material that has settled in the slots are pressed through by the passing balls and do not remain in the diaphragm.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

USE THE ROI CALCULATOR FOR CHRISTIAN PFEIFFER DIAPHRAGMS

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

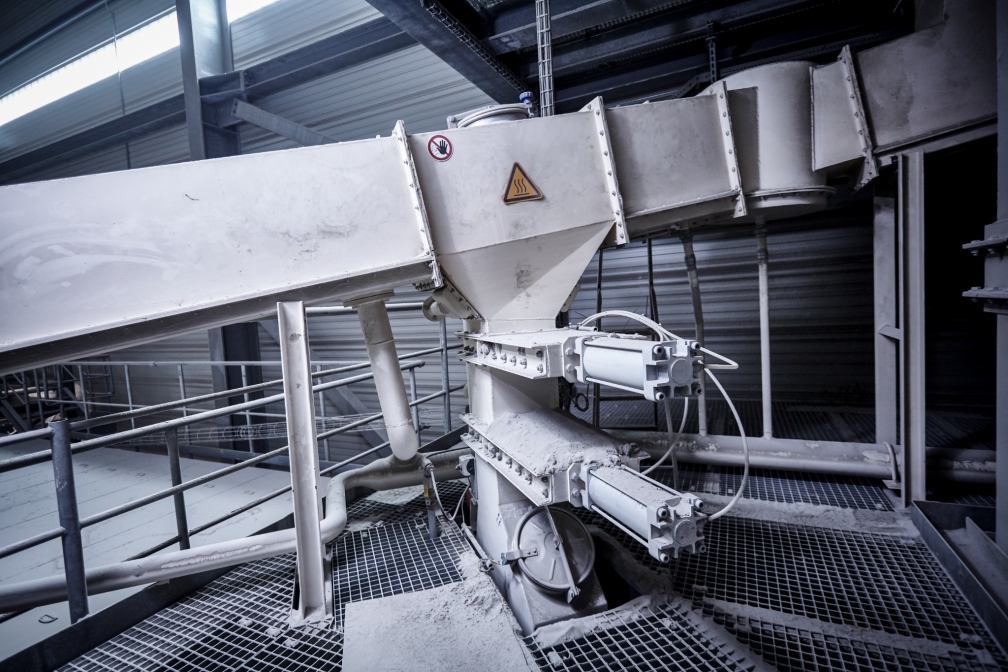

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.