Perfetcly sorted

grinding balls with

the sorter

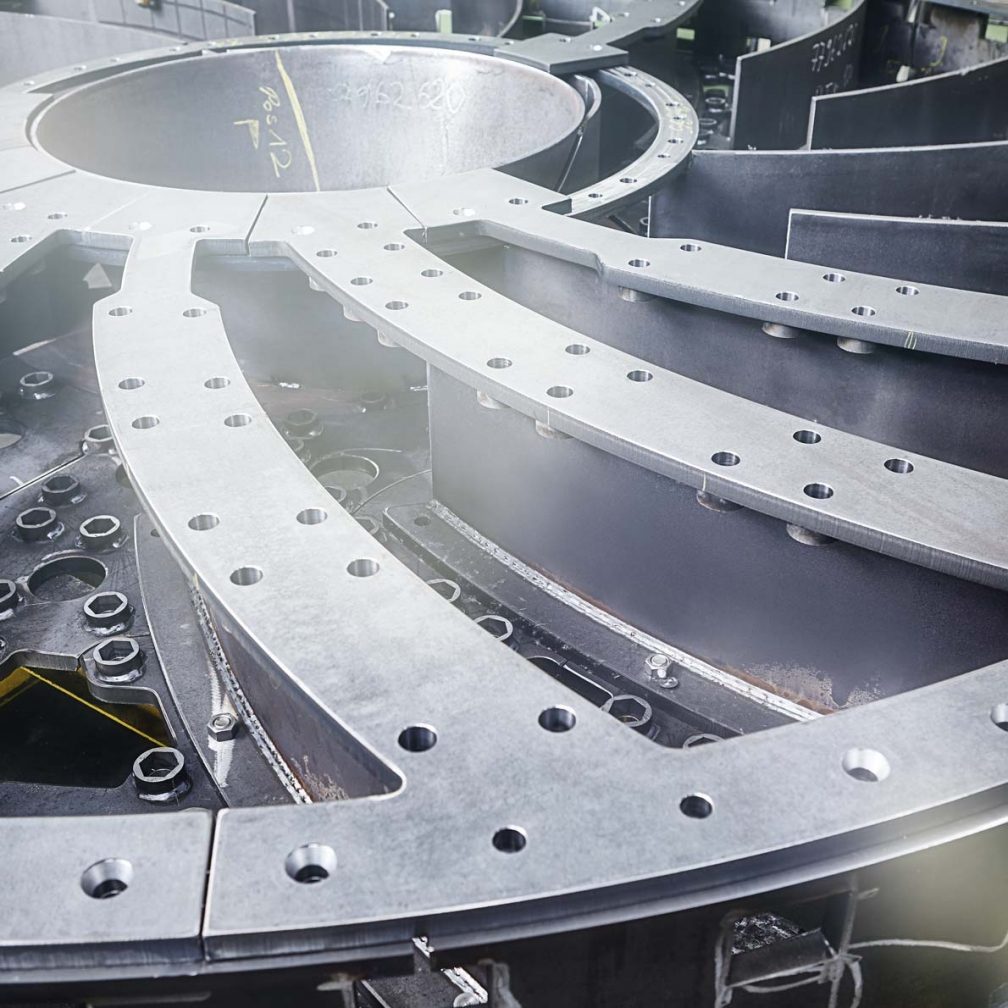

Sorting and Using grinding balls more efficiently

Grinding balls such as Allmax® grinding balls are extremely robust and have a long working life. With a grinding ball sorting machine by Christian Pfeiffer, their use becomes even more efficient. This is because the grinding balls can be precisely checked after passing through the sorting machine. Following the check, they can, be either reused or replaced by new balls – depending on wear.

Technical details

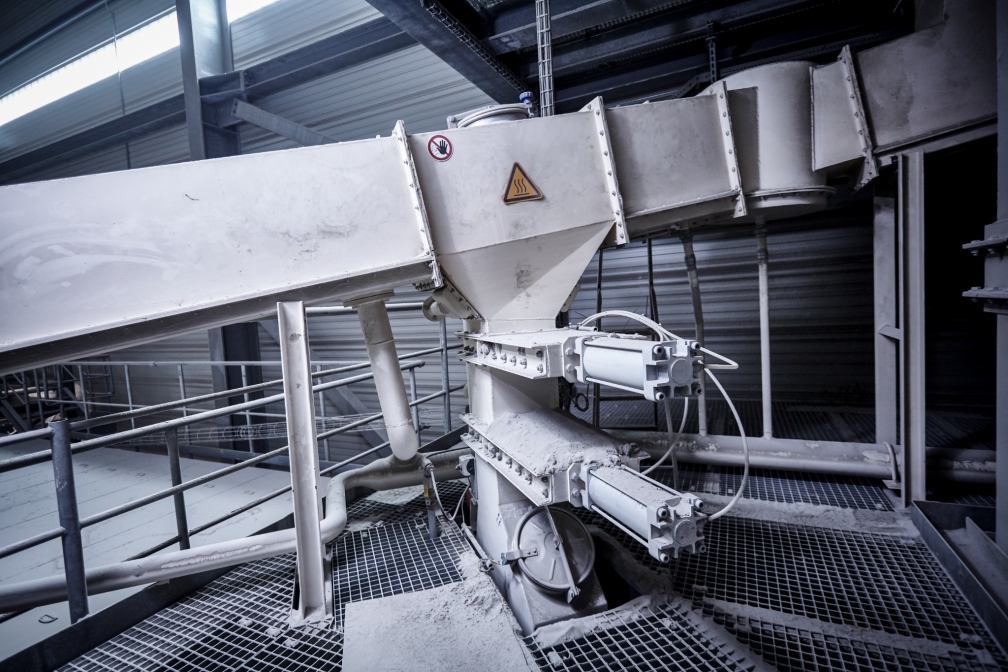

- Sorting machine with two sorting cylinders: Ideal for ball diameters from 50 - 100 mm

- Sorting machine with five sorting cylinders: Ideal for ball diameters up to 50 mm

- Sorting capacity up to 12 t/h (depending on ball size)

- Adjustable vibration feeder and cylinders for optimum sorting performance

- Adjustable input/output gap between the cylinders

- Continual good sorting from the first moment on

- Transportable in two units using forklifts and cranes

- Exceptionally solid construction

Why is it important to sort the ball charge?

The comminution of the material is caused by the movement of the grinding balls. The grinding ball size and quantity ratio play the decisive role for a good grinding result. They determine the relation of effectiveness and quality during grinding.

Due to natural wear, individual ball sizes are frequently refilled. This procedure changes the quantity ratio of the ball sizes and leads to a reduction in the product quality. At the latest when the product quality does not match the requirements, the ball charge should be sorted. The ball charge is removed from the mill and filled into the SORTER, where the balls are sorted by size and the mass fractions are determined. After sorting, the ball charge can be reused. To ensure constant plant operation, it is recommended to carry out this procedure annually for coarse grinding chambers and every two to three years for fine grinding chambers.

Sorting with the Christian Pfeiffer SORTER has a positive side effect: The integrated scrap ejection cleans the ball charge from broken or strongly deformed balls, which have a negative influence on the grinding efficiency.

Is there rental equipment or ball sorting as a service?

Yes, because the SORTER is designed to be both mobile and transportable. The ball sorting machine can be shipped via container. At the Christian Pfeiffer headquarters in Germany, there is a rental SORTER that is designed for this purpose.

Ball sorting machines are rarely utilized to capacity in one plant. Therefore, it can economically make sense to use a ball sorting machine across plants and operate it in a centrally coordinated manner.

How accurate is the SORTER?

Typically, between three to six different grinding ball sizes with size differentiation of up to 50mm are used in a grinding chamber. Our sorting machines can be adjusted continuously between the smallest and largest ball size and with up to eight size ranges. The sorted ball charge can easily be divided in classes.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.